Lorem industrias et range

Pelagus applications sunt ut sequitur:

I. Et curatio organicum vastum vapores in automotive et machinery vestibulum industria, pingis lineas et furnorum;

II. In electronic vestibulum industria, curatio organicum vastum vapores ex typis circuitu tabulas (PCBS);

III. Electrical vestibulum industria, in treatment of filum electorum;

IV. Et lux industria, curatio organici vastum vapores ex calceus, faciens et gluten-coating;

V. Treatment organici vastum vapores a printing et color printing;

VI. Et curatio organicum vastum vapores generatae in variis locis, ut metallurgical et ferro industria, quod productionem carbonis Electrodes, in eget industria, in synthesis de eget processibus (ABTHESITIS), et PETROLEUM processibus.

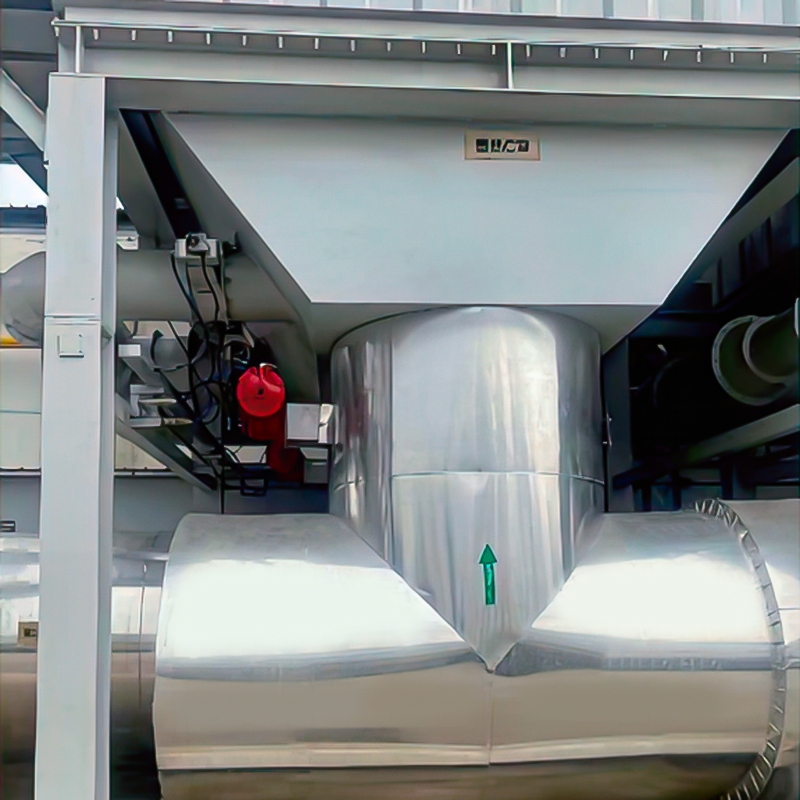

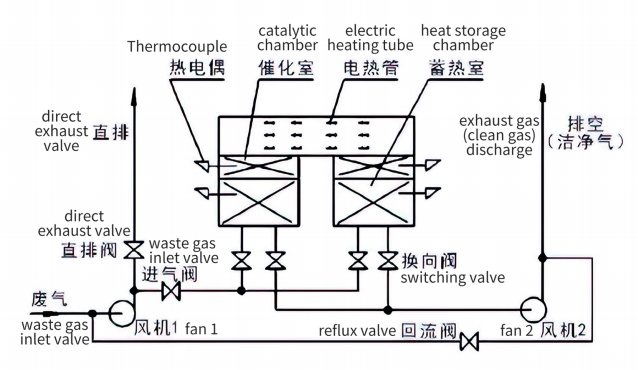

Operating principle

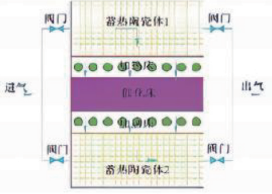

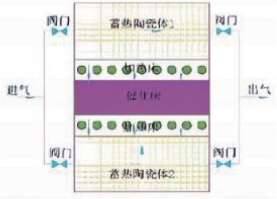

Antequam incipiens processus perditio Gas curatio, calefactio camera et calor repono lectum in fornace non preheated. Post preheating in vastum Gas fons connexa apparatu. Under the action of the matching fan, the organic waste gas first undergoes heat exchange with the preheated heat storage ceramic body 1, enters the heating zone after a temperature increase, and then receives a second temperature increase in the heating zone until the temperature of the waste gas reaches the temperature required for the catalytic reaction. Vastum Gas intrat catalytic locus agere, generating ipsum dioxide et aquam, et releasing calor industria. Et tractata mundus gas patitur calor repono cum calor repono Ceramic corpus II et dimitti a fan. Post temperatus deprehendatur in sparsus Temocouthupus ad exhaurit ventilabrum et valvae switched et vastum Gas ingreditur calor adipiscing Ceramic corpus I. Hic cycle repetit Ceramic Corpus I.

Processus fluxus

| Processus I | Processus II | |

| Simple schematic diagram |  |  |

| Primum camera | Calor effusio per exhauriunt Gas EXERCUS calor repono Ceramic corpus I | Tersus Gas defluxiones Calor adipiscing Ceramic corpus I absorbet æstus |

| Et secundo camera | Tersus Gas defluxiones Calor adipiscing Ceramic corpus II absorbet calor | Calor effusio per exhauriunt Gas EXERCUS calor repono Ceramic corpus II |

| In combustione camera | CATALYTIC COMMECOMPOSITIO | |

Technical features

I. Non secundarium pollutio et non nox generatae ex humilis-temperatus oxidatio et corrumpitur ad CCL ad 500C.

II. Excelsus purificationis efficientiam, usque ad XCV% ad duo gazophylacia et super XCVIII% ad tres gazophylacia.

III. Humilis industria consummatio. Using Advanced calor repono et calor commutationem technology, et industria consummatio potest esse quod humilis ut 8W · hr / nm³.

IV. High gradu automation, tutum et certa operatio, et securus procuratio.

V. Rco habet commoda humilis exhauriunt Gas temperatus et humilis operating costs, et ejus scelerisque recuperatio efficientiam potest plerumque pervenire super XCV%.

Equipment

| Exemplar | Rco-X | Rco-XV | Rco-XX | Rco-XXX | Rco-XL | Rco-L | Rco-LX | Rco-LXXX | Rco-C | Rco-CL | Rco-CLXXX | Rco-CC |

| Treatment Aeris Volubilis (M³ / h) | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 15000 | 18000 | 20000 |

| Typus de vastum Gas esse tractata | Benzene, ketone, adipem, alcohol, aether, aldehyde, phenol et alia organicum vastum vapores et odores. | |||||||||||

| Temperies | CCC ℃ -500 ℃ | |||||||||||

| Purificacionis Efficens | ≥99% | |||||||||||

| CREPITUS-probationem forma | Type membrana | |||||||||||

| Moles calor accumulator (l) | 288 | 512 | 548 | 970 | 1160 | 1570 | 1800 | 2600 | 3200 | 4610 | 5410 | 6280 |

| Moles Catalys (L) | 72 | 128 | 162 | 242 | 288 | 392 | 450 | 648 | 800 | 1160 | 1360 | 1570 |

| Heating Power (KW) | 30 | 36 | 42 | 54 | 65 | 75 | 90 | 120 | 150 | 200 | 250 | 300 |

| Longitudo L (mm) | 1350 | 1650 | 1800 | 2100 | 2300 | 2600 | 2700 | 3200 | 3500 | 4100 | 4400 | 4700 |

| B (mm) | 1350 | 1650 | 1800 | 2100 | 2300 | 2600 | 2700 | 3200 | 3500 | 4100 | 4400 | 4700 |

| Altitudo h (mm) | 2600 | 2700 | 2800 | 3100 | 3200 | 3300 | 3500 | 4000 | 4500 | 5000 | 6000 | 6500 |

| Air Duct (mm) | Φ200 | Φ220 | Φ250 | Φ300 | Φ350 | Φ400 | Φ450 | Φ500 | Φ600 | Φ700 | Φ750 | Φ800 |